GW’s Top 10 Projects of 2024

As we mark our 35th anniversary in 2024, General Welding & Fabricating is proud to look back on a year filled with incredible projects that showcase the diversity and craftsmanship we bring to Western New York. We’re known for trailers and snow removal equipment, but custom metalwork and unique manufacturing projects is our expertise! This year reminded us just how far-reaching and impactful our work has become.

Here are our Top 10 Favorite Projects of 2024—a testament to our commitment to quality, creativity, and community partnerships.

1. North East Tap Co.’s Tap Truck Repairs

North East Tap Co. has creatively transformed a 1969 Fire Engine into a mobile bar truck, aptly named their tap truck. This innovative idea caught our attention, and we were eager to contribute in any way we could. Their team needed a custom support bar fabricated on the driver’s side of the truck to ensure both safety and functionality, and we were more than up for the challenge.

Our skilled fabricators worked closely with North East Tap Co. to design a sturdy, custom-made support bar that seamlessly integrated with the truck’s aesthetic and practical needs. This collaboration highlighted how our expertise in fabrication can bring even the most unique visions to life.

North East Tap Co.’s mobile beer tap truck isn’t just a vehicle; it’s a testament to creativity, innovation, and dreaming big. We’re proud to have played a role in turning their vision into reality.

2. 1966 Sunbeam Tiger Frame Repair

Restoring the Heart of a Classic! This year, we had the privilege of working on a rare automotive treasure: a 1966 Sunbeam Tiger. Known for its compact size and powerful V8 engine, the Sunbeam Tiger is a classic that commands respect among car enthusiasts. However, age and wear had taken a toll on its frame, and it needed expert attention to restore its structural integrity.

Our team at GWFab meticulously assessed the frame, identifying areas compromised by years of use. Using precise welding techniques and high-quality materials, we brought the frame back to its original strength and alignment, ensuring the car was safe and ready for the road.

Restoring the Sunbeam Tiger wasn’t just a repair job—it was a labor of love for a piece of automotive history. Projects like this remind us why we’re passionate about fabrication: combining skill, craftsmanship, and care to breathe new life into something iconic.

3. Shaping the Future at Northland Workforce Training Center

This year, our President, Mark Andol, had the honor of visiting the Northland Workforce Training Center to share insights with the next generation of welders and fabricators. During his speech, Mark emphasized the importance of skilled trades in shaping our communities and the boundless opportunities available in the welding and fabrication industry.

Andol’s visit wasn’t just about inspiring students—it was about forging connections and empowering individuals to dream big. By sharing his journey and expertise, Mark encouraged these aspiring welders to take pride in their craft and pursue careers that are both rewarding and impactful.

At GWFab, we believe in building more than just steel structures; we’re passionate about building up people, too. Collaborating with Northland underscores our commitment to education, mentorship, and the future of skilled trades in Western New York.

4. Decorative Steel Gate Door

When a client came to us with a vision for a decorative gate panel, we knew this was an opportunity to blend artistry with precision engineering. The design featured intricate patterns that required both meticulous craftsmanship and advanced fabrication techniques to bring to life.

Our team at GWFab carefully cut and welded the steel to ensure every detail was flawless. The result was a stunning gate panel that not only provides security but also serves as a striking architectural feature.

This project exemplified our ability to transform raw steel into a functional work of art, demonstrating how even everyday structures can have beauty and character when created with care and expertise.

5. Custom I-Beam Railings for Lackawanna High School

When Lackawanna High School needed railings that combined strength, safety, and a touch of school spirit, GWFab was ready to deliver. This project involved fabricating custom I-beam railings that not only met the highest safety standards but also celebrated the school’s identity.

Our team crafted the railings with precision, ensuring they could withstand heavy use while incorporating design elements that reflected the school’s pride. The final installation was a seamless blend of form and function, showcasing the durability of heavy-duty steel alongside creative flair.

This project highlights how even practical structures like railings can serve as a symbol of community pride when designed and fabricated with care. At GWFab, we take pride in building pieces that stand the test of time and connect with the people who use them.

6. ConEquip’s Steel Planet Sign

When ConEquip Parts approached us to create custom steel logos for their business, we knew this project called for precision and artistry. These logos needed to make a bold statement while reflecting the company’s strength and reliability.

Using high-quality steel and advanced fabrication techniques, we brought their design to life, creating logos that were both visually striking and incredibly durable. We even lined the entire logo with LED lights to make it pop! Whether displayed in an office or outdoors, these steel logos are built to endure the elements while maintaining their polished look.

This project showcases how GWFab transforms ideas into tangible, impactful pieces that not only represent brands but also stand as lasting symbols of quality and craftsmanship.

7. Buffalo Olde Brewing Custom Ladder System & Mezzanine

Buffalo Olde Brewing faced a unique challenge: they needed a reliable and customized ladder system to enhance their brewing operations, all while working within the brewery’s limited space. GWFab was thrilled to take on the task, crafting a solution tailored to their specific needs.

Our team designed and fabricated a ladder system that prioritized safety, durability, and efficient use of the available room. The compact yet sturdy design fit seamlessly into their brewing setup, ensuring maximum functionality without wasting an inch of space.

This project demonstrates how GWFab’s expertise in custom fabrication helps local businesses overcome spatial limitations with innovative solutions—allowing Buffalo Olde Brewing to focus on what they do best: crafting exceptional beer.

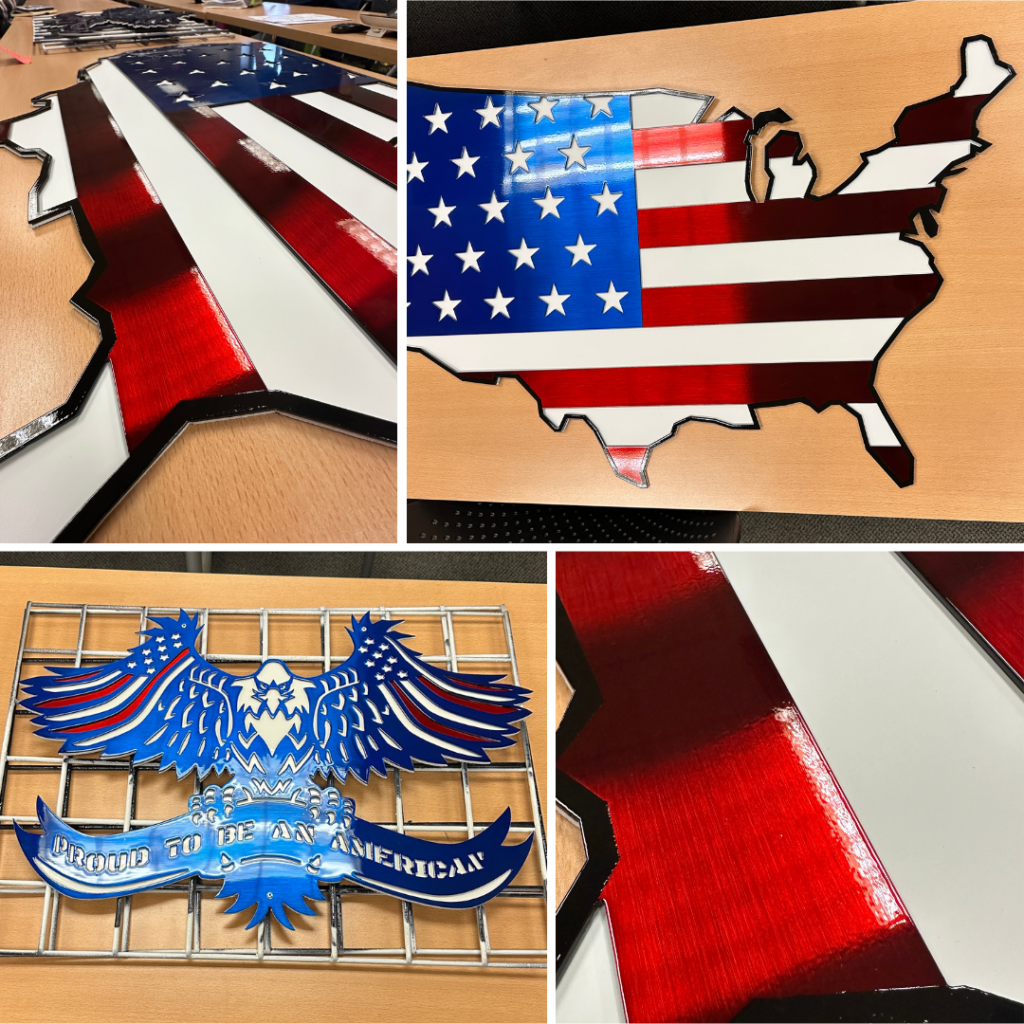

8. Custom American Flag & Eagle Pieces

At GWFab, we’re proud to manufacture steel art pieces that celebrate patriotism and craftsmanship, many of which are displayed and sold at the renowned Made In America Store. These iconic designs, featuring American flags and eagles, are a favorite among customers who value quality and symbolism.

For one of our clients, these pieces weren’t just art—they were an opportunity to create something even more unique. The client loved our designs but envisioned steel borders and accents to elevate the look further. Our team eagerly took on the challenge, customizing the pieces to add intricate details that enhanced their beauty and durability.

This project is a perfect example of how we can tailor our work to meet individual preferences, combining artistic creativity with precise fabrication. Whether displayed in homes, businesses, or public spaces, our custom steel art pieces stand as timeless tributes to American pride.

9. Steel Buffalo Home Number Sign

Custom steel creations are one of our specialties at GWFab, and this project was no exception. A homeowner wanted a unique way to display their address while showcasing their Buffalo pride. We worked with them to design and fabricate a custom steel home number sign featuring a bold Buffalo motif.

Our team combined precision cutting and expert craftsmanship to create a piece that was both functional and artistic. The sign not only serves as a practical address marker but also as a striking decorative feature that celebrates the homeowner’s connection to Western New York.

This project highlights how GWFab can turn simple ideas into custom steel masterpieces, blending style and utility to create one-of-a-kind solutions. Whether for residential or commercial use, we bring visions to life with quality that lasts.

10. Dome Restoration Ladder for OLV National Shrine & Basilica

As part of the ongoing restoration of the historic Our Lady of Victory National Shrine & Basilica, GWFab was honored to contribute to this landmark project. The challenge was to fabricate a custom ladder for the basilica’s iconic dome, ensuring safe access while respecting the architectural beauty and historical significance of the structure.

This project exemplifies our ability to handle complex and meaningful projects, combining engineering expertise with an appreciation for the history and beauty of Western New York’s treasured landmarks. We’re proud to have played a role in preserving this piece of our community’s heritage.

Honorable Mentions

While these didn’t quite crack the Top 10, they deserve a special shoutout for their creativity and craftsmanship:

- OLV Staircase Siding Install

- OLV Front Steel Bracket Covers

- Steel Ice Shields

- Front Bumper Protector

- Custom Large Ladder Rack

- ConEquip’s Mirror Sheen Polished Logo Sign

- Heavy-Duty Hitch Plate Install

Looking Ahead to 2025

As we celebrate 35 years of serving Western New York, we remain dedicated to innovation, quality, and collaboration. Whether it’s repairing a vintage car, designing custom trailers, or crafting one-of-a-kind metalwork, you dream it, we build or repair it!

📍 991 Maple Road, Elma, NY

📩 info@GWFab.com

📲 gwfab.com